Now onto the building...

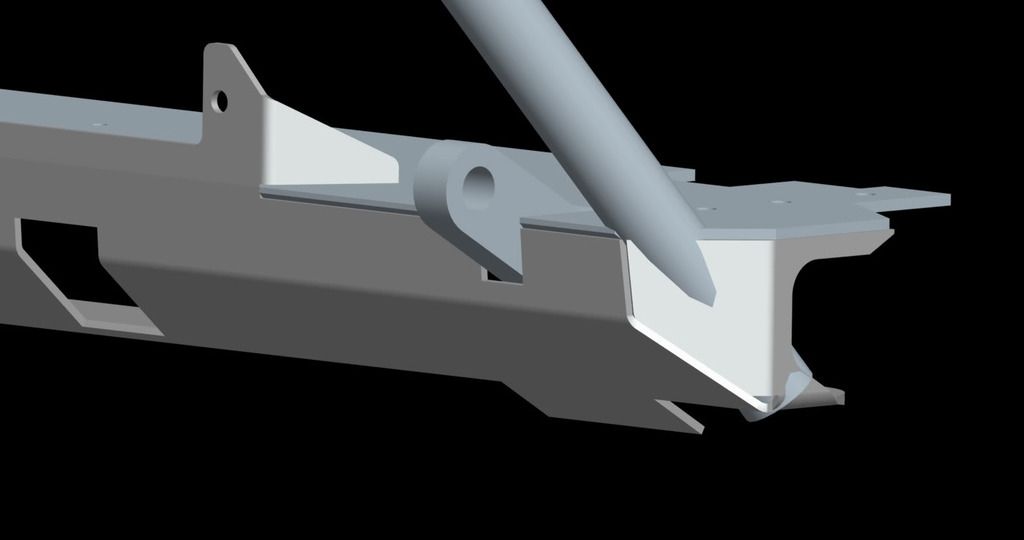

Been designing various items for the jeep over the past few months.

So I sent out the flat state dxfs to a few local shops for some laser cutting. Ended up getting a good Quote $160 for material + cutting which all got delivered on Friday. Today I spent the day in the shop bending up the plate and welding it together.

.

Dry fit, snapped together as planned.

So before I could start tacking it together I had to make a jig, since I couldn't get the jeep into the area with the welder... I had to make a "fram" jig out of some 2x4 rect tubing

Start tacking and filling the gaps with the mig

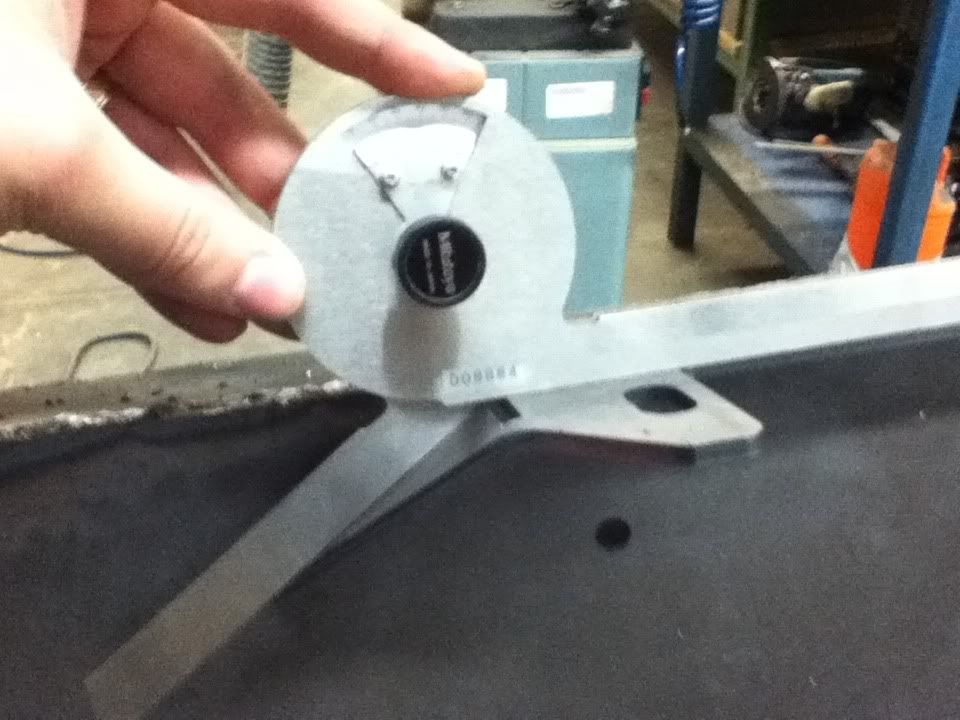

Making some final measurements and final bends.

And start connecting the dots.

I've still got a lot of cleanup to do, and some pipe to bend and weld on, but it's looking pretty decent already after only a days work.